What Is Principle Of Auger Filling Machine?

August-03,2018

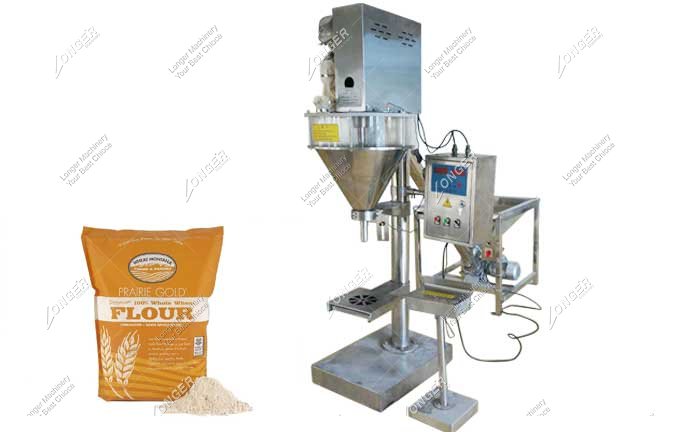

First of all, we need to understand that the auger type powder filling machine is usually suitable for powder, such as washing powder, pancake powder, flour, ground coffee, protein powder or milk powder. These products are also called non-free-flowing products. These products do not flow as directly as solid particles when tilted downward.

A non-free-flowing product requires you to use a compressed flight drill to compress. The compressed flight drill has one or two spiral drills that extend up to the bottom of the funnel to grab the product and compress it. The compressed product can be conveniently placed into a funnel for further quantitative filling. A funnel for a non-free-flowing product, together with a compression drill, which is used to capture non-free-flowing products and help package them. It has great influence on the filling success.

It is important for the auger filling machine operator to understand these problems. These problems are also very important for the manufacturers of machines. In order to create the perfect funnel and compression drill, we have absorbed many advanced technologies. After many experiments, we have applied the perfect funnel and compression drill to our machine. The machine has reached the international advanced level in many aspects.

Advantages of anger filling machine:

1.Packing speed and bag length can be adjusted without grade within rated range without replacement of parts. The length of the bag making machine is set by the controller of the packaging machine, which makes the bag length adjustment simple and convenient, the length of the bag making is accurate, and the operation is stable and reliable.

2.All parts that come into contact with the packaging materials are made of stainless steel or non-toxic materials, meeting the hygienic standards of the food industry and the pharmaceutical industry.

3.The heat seal body adopts four-way heating control. The heat seal temperature can be set in advance and the temperature can be controlled automatically to ensure a good heat balance.The machine is suitable for many kinds of packing materials.

4.High quality photoelectric switch is used to detect and locate the color mark printed on the packaging material, so that the finished packaging product can obtain the complete trademark pattern.

Our company has professionals who can solve theoretical problems related to machines. If you have anything you want to know, please contact us. Good luck filling!